Carbon dioxide, also known as R744, is experiencing a renaissance as a refrigerant in vehicle air conditioning. This gas, with a long history in refrigeration dating back to the 19th century, offers numerous advantages, such as no ozone depletion potential. Its special properties make CO2 an attractive alternative to conventional refrigerants like R134a and R1234yf.

Advantages of CO2 as a Refrigerant at a Glance:

Eco-friendliness: It has no impact on ozone depletion and a low global warming potential.

Safety: Chemical inactivity, non-flammability, and low toxicity.

Cost: CO2 is cost-effective and does not require elaborate recovery and disposal measures.

High Refrigeration Performance: Compared to other refrigerants, CO2 offers significantly higher volumetric refrigeration performance.

Challenges and Requirements

Despite these advantages, there are challenges in using CO2 as a refrigerant, particularly due to its high pressure range and low critical temperature. These characteristics necessitate special system designs and materials to withstand the high pressures.

The Role of DDM Pressure Sensors

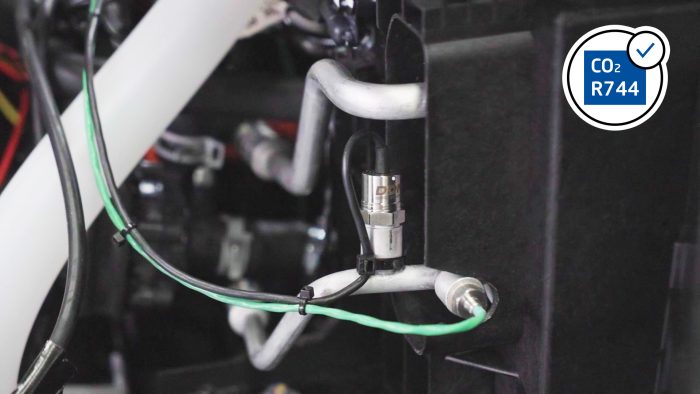

For the development and testing of CO2-based air conditioning systems, DDM pressure sensors are ideally suited. With their seal-less, wear-resistant diaphragm made of 1.4435 stainless steel and a housing of stainless steel 1.4404, these sensors are chemically resistant to CO2. The 100% helium leak test ensures first-class quality of the laser welds, which is mandatory due to the high pressures in CO2 systems. Our sensors have been extensively tested both on test benches and in real vehicle operation and have proven themselves many times over in the testing of CO2 air conditioning systems. DDM pressure sensors impress with long-term stability and precision. You can choose between various sizes, temperature ranges, and output signals – customized for client-specific applications and demanding measurement tasks.

CO2 as the Refrigerant of the Future in Vehicle Air Conditioning

Given the growing concerns about the environmental impacts of traditional refrigerants, CO2 is gaining importance as an alternative solution. Experts from the automotive industry predict that in the coming years, all new vehicles could be equipped with CO2-based climate systems. This reflects not only the industry’s commitment to more environmentally friendly solutions but also confidence in the reliability and efficiency of CO2 as a refrigerant.

DDM Pressure Sensors as Ideal Supporters of Your Development Work

Using CO2 as a refrigerant in vehicle air conditioning systems represents a promising, environmentally friendly alternative that offers both high performance and safety. DDM pressure sensors are an essential component for the development and validation of these innovative systems, ensuring the necessary accuracy and reliability under extreme operating conditions. With advancing technological developments and growing environmental awareness, CO2 is likely to play a central role in the future of vehicle air conditioning.