We are specialists in the development of sensors and systems for pressure and flow measuring. In doing so, we face complex and unprecedented tasks and requirements. Our experienced team dedicates itself to every single development with professional competence and passion. In our application reports you will know more about our work and competence.

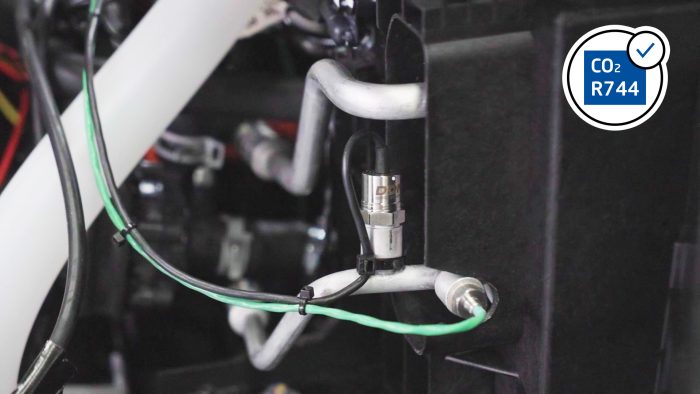

Carbon Dioxide (CO2) R744 as a Refrigerant DDM Pressure Sensors in Vehicle Air Conditioning Systems for Testing New Refrigerants

Carbon dioxide, also known as R744, is experiencing a renaissance as a refrigerant in vehicle air conditioning. This gas, with a long history in refrigeration dating back to the 19th century, offers numerous advantages, such as no ozone depletion potential. Its special properties make CO2 an attractive alternative to conventional refrigerants like R134a and R1234yf.

Thermal management in electric vehicles Turbine flow measurement systems for testing thermal management in electric vehicles

Optimized thermal management systems for electric vehicles contribute to energy-efficient, economical and comfortable mobility. Turbine flow measurement systems made by DDM are a tailor-made measurement technology for on vehicle thermal management testing.

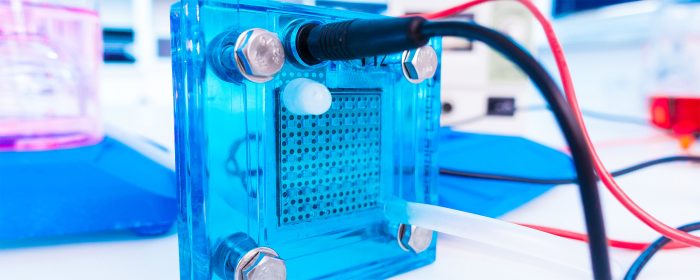

Pressure sensors for hydrogen fuel cells Hydrogen-suitable pressure sensor for the development of a more efficient fuel cell

Hydrogen has become an indispensable part of the future energy mix. Our team supported a large research laboratory in the development of new and more efficient fuel cells. In the context of a long-term test carried out over 4 months of a low-temperature polymer electrolyte membrane fuel cell stack, DDM pressure sensors were used in the anode path of the stack. The media compositions at the pressure sensors corresponded to realistic compositions. The involved medium consisted of different concentrations of hydrogen, nitrogen, water vapor and liquid water. The sensing element and pressure connections of our hydrogen-compatible pressure sensors are made from 316L stainless steel. The construction is fully welded and 100% helium leak tested. Each sensor is supplied against a manufacturer declaration for hydrogen use.

Digital RF speed sensor / TTL Pickoff for the sustainable upgrade of existing turbines

In some cases, existing turbine flow meters that are still running well are taken out of service because the associated instrumentation system does not perform with reliable flow readings any more. These faults, for example indicate readings at now flow and the other way round. More serious are flow rate readings with increased uncertainty. Malfunctions are more likely caused by the electronic part of the measurement system rather than by the turbine flow meters itself.

Differential pressure sensors for thermal management Differential pressure sensor suitable for road tests for measuring the differential pressure in thermal management

Even in modern hybrid or electric vehicles, heat is produced as a waste product, or heat and cold are required to supply the power electronics, the drive, the battery and also the passenger compartment with the optimum temperature in each case.

To coordinate these extensive tasks of the cooling system, an elaborate and complex thermal management system is required.

Pressure sensors Brake / road tests Miniature sensor for measuring the dosing capability and constancy of the brake pressure

Regardless of whether vehicles are powered by combustion engines, hybrids or electric drives, every vehicle must be braked as reliably and safely as possible. In addition to electrical recuperation, this is done via hydraulic brakes.

Flow meters for the food and beverage Precise flowmeters for the food and beverage applications – small and cost-effective

Pelton wheel flow meters are small and cost-effective flow meters for liquids and are suitable for batching processes and dispensing applications particularly within the food and beverage, chemical and laboratory sectors.

Pressure sensor for filling systems Customised for client-specific requirements

The filling of complex systems requires a sophisticated filling process. A time-optimised process with short cycle times is crucial when it is about economic efficiency. To permit the most rapid filling a number of process steps are required. Their dynamic sequence is determined by the geometry of the unit to be filled and by the fluid properties of the filling medium itself. The typical areas of application are refrigerators, air conditioning systems, heat pumps, systems for braking, cooling, air conditioning, engines, gearboxes, hydraulics or windshield wiper systems. The most important parameter for a short cycle is the process pressure. It is crucial that the pressure sensor is fully integrated within the hydraulic system to respond immediate for any pressure change.

Differential pressure sensors: measuring pressure pulses Measuring pressure pulses in vehicles – miniaturised and fast

Vehicles product quality is perceived via various human senses: In addition to smell, optics and haptics, acoustics also influence the perceived driving comfort and the sense of well-being when driving.

Among others one important factor, is the pressure impulse that occurs when the doors of a vehicle are slammed. If this peak pressure is too high, it can be very unpleasant for the ears. In addition, too much pressure inside the vehicle can also prevent closing and the doors completely.

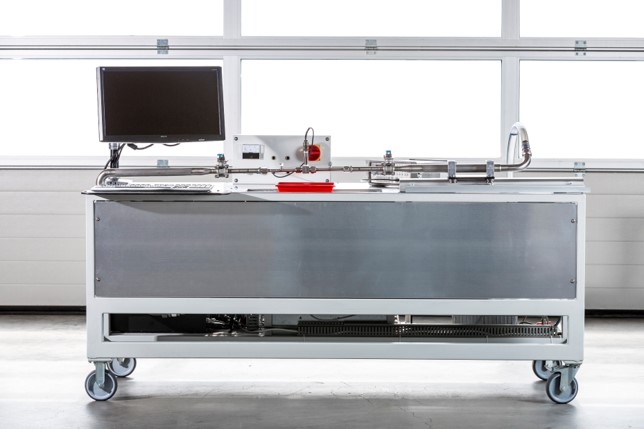

Development of flow calibrators Customised flow calibrator for time- and cost-efficient development and production

The calibration of flow meters is a complex process. Generally speaking, this work is carried out by calibration laboratories having the appropriate technical equipment. In addition to the calibration costs, there is the downtime which may be significant for the customer.

Space technology: Pressure sensors for weightlessness Stable high-precision pressure sensor for experiments in space travel

Various experiments of a biological, chemical or physical nature are carried out at an almost daily basis on the ISS space laboratory. Reliabilty of instrumentation is the most important factor. Therefore some of the experiments were tested on Earth under weightlessness simulated. This is why those instruments are temporary brought into the orbit with small rockets. In this context, for the measurement of various electrical and physical parametres, highly precise and reliable sensors are essential. Therefore the DDM pressure sensor PV 15 series was selected and proven to perform as expected.

Various experiments of a biological, chemical or physical nature are carried out at an almost daily basis on the ISS space laboratory. Reliabilty of instrumentation is the most important factor. Therefore some of the experiments were tested on Earth under weightlessness simulated. This is why those instruments are temporary brought into the orbit with small rockets. In this context, for the measurement of various electrical and physical parametres, highly precise and reliable sensors are essential. Therefore the DDM pressure sensor PV 15 series was selected and proven to perform as expected.

Flow meter for agriculture / agribusiness for the delivery of liquid media as required

To be able to operate agricultural cultivation economically, you have to use fertilizers and pesticides.

An excessively high dosage is costly, damages the soil and groundwater.

Liquid fertilizers and pesticides can be applied in a more targeted manner according to the soil behavier.

DDM flow meters are robust and media-resistant. They measure the flow rate in real time, allowing exact dosing at high driving speed and documentation of the amounts of plant agents applied.

Turbine measuring system: thermocouple versus Pt100 or Pt1000 Accuracy, dynamics and installation space in comparison

Turbine flow meters are dependent on the viscosity of the medium. In order to compensate for this effect, the fluid temperature is measured in the best case in contact with the medium. With the aid of a stored temperature to viscosity characteristic curve, the current media viscosity is calculated.

The wetted temperature measuring point in a measuring turbine is realized either by means of a Pt100/1000 resistance thermometer or via a thermocouple. These two temperature measurement methods are common in the industry and are used in many ways.

The following table compares the performance of these two temperature measurement methods in the application area of a turbine measurement system. Afterwards, the most important parameters accuracy, dynamics, installation space and cabling will be discussed in detail in the comparison. In addition, you will learn all about the added value of our in-house developed DDM turbine flow measurement system with thermocouple VCT.