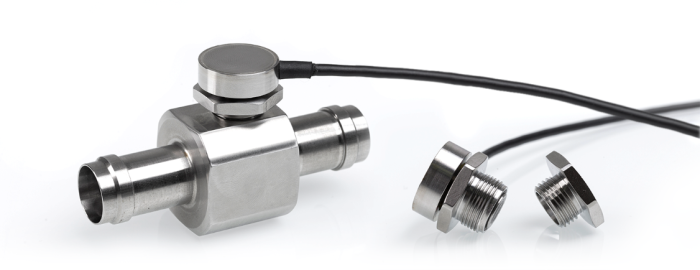

Upgrade instead of discard! Our small digital RF pickup (Smart-Pickup) is an intelligent sustainable add-on for every existing turbine flow meter.

The consistent drive for miniaturization and sustainability inspired us to develop the DDM Smart-Pickup. Pickups on the market with built-in RF signal amplifiers usually take up too much space, and RF pickups without signal amplification are susceptible to interference due to the exposed RF resonant circuit. The innovative DDM smart pickup is highly miniaturized and can digitalize the RF signal inside, ensuring a reliable TTL high level digital pulse output signal. Another advantage for maximum flexibility and minimum space requirements: the electrical connection comes with a high temperature cable and freely adjustable orientation

Almost any existing turbine flow meter system can be upgraded to the current state of the art by using our DDM Smart-Pickup. Keep your turbine flow meter running just upgrade the electronics while your meter is calibrated next.

The consistent drive for miniaturization and sustainability inspired us to develop the DDM Smart-Pickup. Pickups on the market with built-in RF signal amplifiers usually take up too much space, and RF pickups without signal amplification are susceptible to interference due to the exposed RF resonant circuit. The innovative DDM smart pickup is highly miniaturized and can digitalize the RF signal inside, ensuring a reliable TTL high level digital pulse output signal. Another advantage for maximum flexibility and minimum space requirements: the electrical connection comes with a high temperature cable and freely adjustable orientation

Almost any existing turbine flow meter system can be upgraded to the current state of the art by using our DDM Smart-Pickup. Keep your turbine flow meter running just upgrade the electronics while your meter is calibrated next.

DDM pressure sensor qualified for hydrogen use.

DDM’s established pressure sensor PV-22 series have been qualified for hydrogen use. Hydrogen has become an indispensable part of the future energy mix. DDM hydrogen use pressure sensors perfectly meet the demanding requirements of hydrogen driven truck road test as well as development work on more efficient fuel cells.

DDM’s established pressure sensor PV-22 series have been qualified for hydrogen use. Hydrogen has become an indispensable part of the future energy mix. DDM hydrogen use pressure sensors perfectly meet the demanding requirements of hydrogen driven truck road test as well as development work on more efficient fuel cells.

Electrically powered trucks and heavy vehicles with fuel cell technology offer opportunities for more climate-friendly goods transportation. Extensive road tests are necessary when developing such vehicles. The DDM PV-22 sensor has been proven to be reliable under those extreme conditions for years. As a result the new PV-22H2 series are qualified for hydrogen applications.

DDM´s hydrogen use pressure sensors have extensively been tested with various compositions of hydrogen, oxygen, water and water vapour. The pressure modules and process connections are made of 316L stainless steel. They are fit together without seal, fully welded and helium leak tested. The PV-22H2 is supplied with a manufacturer´s declaration for hydrogen use. Well known car manufacturers have already proven the PV-22H2 pressure sensors to be accurate and reliable.

Ideally combined – The measurement of flow and pressure in electrically powered vehicles.

Besides hydrogen pressure sensors, DDM provides powerful flow measurements for on vehicle test of smart battery thermal management systems of electrically powered vehicles. DDM turbine flow meters are highly accurate and extremely miniaturized. Thanks to an integrated media exposed thermocouple DDM turbine meters are corrected for media viscosity changes. A new circuit design for extended EMC protection ensures reliable readings at the vehicle high-voltage environment.

System-Upgrade for flow measurement: Flow turbine meter with media exposed temperature probe. Flow computer with tool free media selection.

The new flow measurement system VCM (Viscosity-Compensated-Measuring) has been designed for the extreme requirements of road testing. The VCT turbine meter as well as the VCA flow-computer have been miniaturized and can be fitted even where space is limited. Every flow turbine meter is equipped with a media exposed temperature probe by default.

The new flow measurement system VCM (Viscosity-Compensated-Measuring) has been designed for the extreme requirements of road testing. The VCT turbine meter as well as the VCA flow-computer have been miniaturized and can be fitted even where space is limited. Every flow turbine meter is equipped with a media exposed temperature probe by default.

VCA flow computer operate with any DDM flow turbine meter. They system is plug and play and will configure itselve after connected. Up to 10 customer-specific fluid characteristics (viscosity vs. temperature) may be stored in the flow computer memory. The medium to be measured can be selected tool free by using an RFID tag. The flow computer generates a viscosity-compensated, analogue output for flow rate and media temperature. Dynamic averaging and low flow suppression can be set. The flow measuring system offers TEDS functionality for the automatic parameterization of connected data acquisition systems.

Enhanced quality management: monitoring of measurement devices with camera based wear pattern support.

In cooperation with one of our customers, we have developed a system linking the measurement data from a conventional calibration procedure with the wear pattern recorded by an endoscope. Device under test (DUT) with abnormale calibration data are visually inspected by an endoscope. Calibration data together with wear pattern supports predictive maintenance decision.

In cooperation with one of our customers, we have developed a system linking the measurement data from a conventional calibration procedure with the wear pattern recorded by an endoscope. Device under test (DUT) with abnormale calibration data are visually inspected by an endoscope. Calibration data together with wear pattern supports predictive maintenance decision.

Depending on the individual application pressure sensors are probably stressed by a high number of pressure cycles, pressure spikes, temperature cycles, shock and vibrations.

For pressure sensors used within a measurement aquipment periodic recalibration is required. Common recalibration procedure is to apply pressure and measure the DUT output signal. A nominal-actual value comparison decides if the deviation is within permissible limits or not. For DUT’s where accuracy over a wide temperature band is important a recalibration at various temperatures can be required.

DDM investigations found more parameter which could decrease the pressure sensor performance. Application-specific contamination or damage of the pressure-sensitive diapragm can affecting the accuracy of the pressure sensor as well. Those mechanically based errors source can be detected by the endoscope camera.

This extended inspection method contributes to a more predictive based quality management.

Read our application reports to learn more.

We look forward to your inquiry and a conversation with you!